Thanks: 0

Likes: 0

Dislikes: 0

-

Super Member

Year Long 3401 Production Review & Rotary Finish Compairson

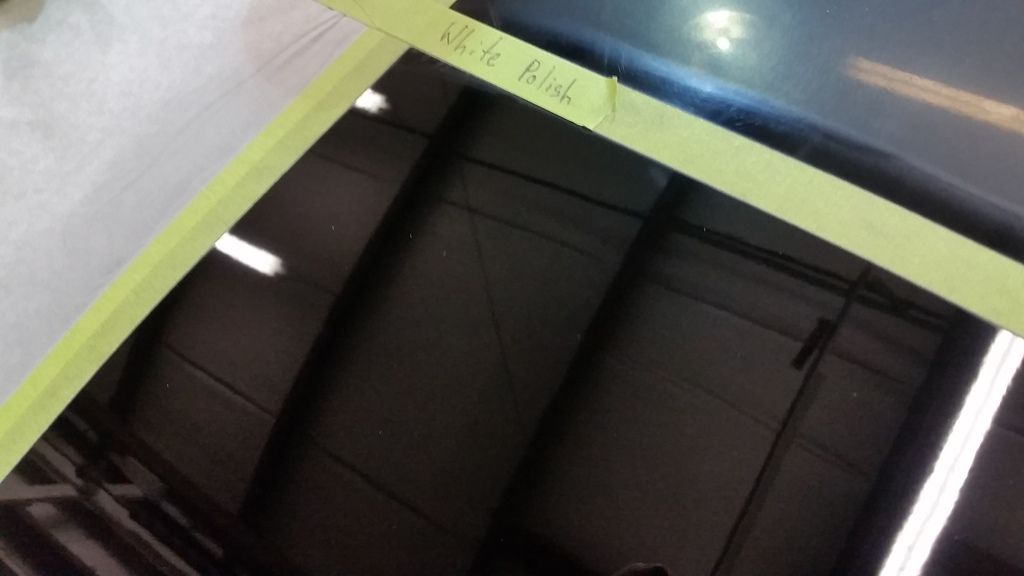

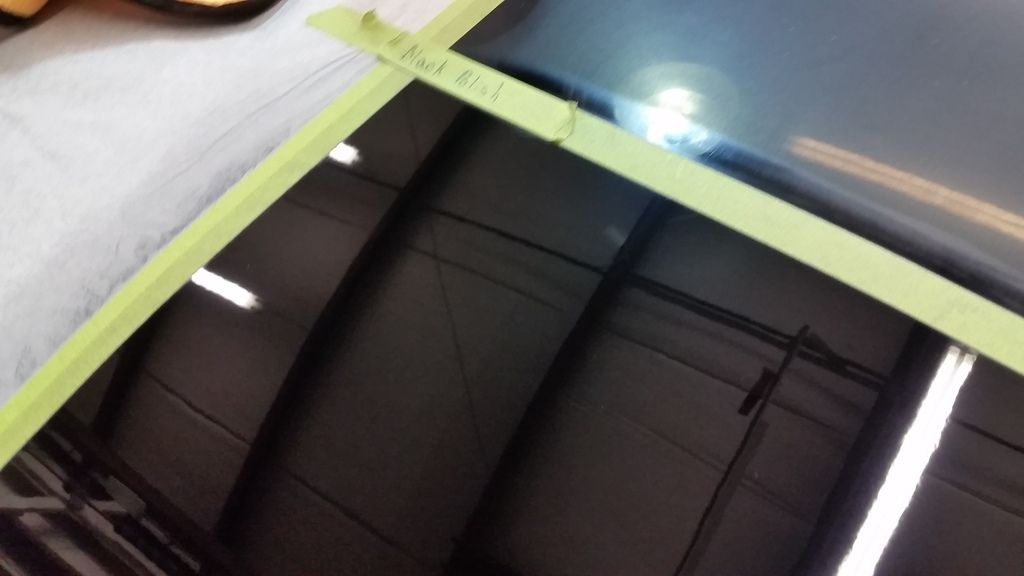

As I had mentioned in this thread FLEX XC 3401 first options? I decided to purchase a Flex 3401 to test at work for assisting with clear coat finishing, mostly on black and really dark colors for hologram elimination. Having used a rotary buffer for many years I would say my skills are just as proficient as the next professionals. Working with recently painted panels (buffed next day) can be difficult as the paint has not fully cured and scratches very easily.

Usually holograms are not something a customer will notice or mention because most cars aren't black and the vast majority of vehicles we paint finish fantastically, but there are exceptions.

Example 1: Seasons and Time of Day

Most forum members will obviously know that a recently polished or corrected vehicle will look way better in the shade vs the sun. In the winter time, when its cold and grey here in the mid-west, holograms aren't a problem because they cant be seen. In the spring and summer months, the sun is high and holograms become much more noticeable. Autumn represents a different story. Don't ask me why, but having painted for 12 years, swirls and holograms are extremely obvious in the fall, especially in the evening. It may be because the sun is lower in the sky, it might be because there is less humidity in the air distorting the light. I'm not sure, but its obvious if you pay attention year to year.

Example 2: Higher end Vehicles

More than 3/4 of the vehicle delivered from our shop are higher end vehicles. Not Lamborghini and Ferrari, but normal DD vehicles involved in accidents such as Lexus, Mercedes, Ford (Mustang GT, Shelby ROUSH) Acura, BMW, you name it. Obviously these customers can be very picky and they should be. They pay their insurance and want their care repaired properly. Saying that, all delivered cars are finished to the best quality physically possible.

I have written all this because I want to spend 2016 periodically updating this thread regarding rotary and dual action buffers/polishers and their finishing qualities at my experience level. This will include Winter/Spring/Summer/Fall for a full spectrum of situations and conditions. I will be doing this at my leisure throughout the year but updating when I can. I'm mainly doing this to log my own experiences and for my own knowledge, but thought some members would like to see what I come up with. This wont be a perfectly written thread and there will be a lot of variable so you will have to take this for what it is.

-

Super Member

Re: Year Long 3401 Production Review & Rotary Finish Compairson

The only buffers/polishers in this thread that will be used unless otherwise specified...

DEWALT Variable Speed Polisher/3M Hookit SBS Backup Pad DWP849

FLEX XC 3401 VRG Polisher/The FLEX XC3401 4 Inch Changeable Backing Plate System/Flex XC 3401 VRG 5.5 inch Backing Plate

-

Re: Year Long 3401 Production Review & Rotary Finish Compairson

That Dewalt looks huge! Flex looks stunning in gloss black.

-

Re: Year Long 3401 Production Review & Rotary Finish Compairson

***Subscribed***

For people not familiar with how discussion forums work. If you want to follow a thread then what you want to do is "subscribe" to the thread. When you subscribe to a thread you will receive an e-mail notice anytime a new post is made to the thread.

This reminds you that,

A: You're subscribed to the thread.

B: To click on the link in the e-mail to instantly go to the thread to read the most recent thread.

If you don't know how to "subscribe" to a thread I have an article on this with pictures showing you what to do.

How To Subscribe to a Thread

-

Re: Year Long 3401 Production Review & Rotary Finish Compairson

To 7PaintGuns,

As you know, having the right tool and pads is only part of the equation. The most important factor in my opinion is to have the best abrasive technology. This is vitally important when it comes to finishing with a dual action polisher otherwise you'll leave tiny scratches in the paint from the abrasive technology.

These tiny scratches are called,

DA Haze (dual action polisher haze)

Tick Marks (a term coined by Meguiar's chemists)

Micro-marring (general term for the scouring appearance caused by low quality abrasive technology used with orbital polishers)

All three of these terms describe the same scratch pattern caused by low quality abrasive technology when used with dual action orbital polishers.

There are other things that cause scratch patterns when using dual action polishers like the pad but keep in mind it's the ABRASIVES that come into contact with the paint surface FIRST not the pad.

Note: Holograms is a term to describe a very specific scratch pattern inflicted into paint by the misuse of a rotary buffer.

Because you paint cars my guess is you're familiar with and use a lot of body shop grade and body shop safe compounds and polishes. Nothing wrong with this just make sure by doing some testing that the products you choose to use either,

1. Are formulated and recommended for use with dual action polishers

And/Or

2. Visually appear to work to your expectations upon your inspection after use.

Here's a little article I wrote on this topic. The article is the result of me answering questions for people NOT getting good results when using the Flex 3401 and tracing the ROOT CAUSE of the issue back to the abrasive technology chosen not the tool or the pad.

For Use with Rotary Buffer Only - Read the Directions

For what it's worth... if a person were to read enough of my articles or replies to others questions they will see that I use the below two words a lot when helping others to troubleshoot root causes of paint finishing problems.

abrasive technology

-

Super Member

-

Super Member

Re: Year Long 3401 Production Review & Rotary Finish Compairson

Originally Posted by Mike.Phillips@Autogeek

To 7PaintGuns,

As you know, having the right tool and pads is only part of the equation. The most important factor in my opinion is to have the best abrasive technology. This is vitally important when it comes to finishing with a dual action polisher otherwise you'll leave tiny scratches in the paint from the abrasive technology.

These tiny scratches are called,

DA Haze (dual action polisher haze)

Tick Marks (a term coined by Meguiar's chemists)

Micro-marring (general term for the scouring appearance caused by low quality abrasive technology used with orbital polishers)

All three of these terms describe the same scratch pattern caused by low quality abrasive technology when used with dual action orbital polishers.

There are other things that cause scratch patterns when using dual action polishers like the pad but keep in mind it's the ABRASIVES that come into contact with the paint surface FIRST not the pad.

Note: Holograms is a term to describe a very specific scratch pattern inflicted into paint by the misuse of a rotary buffer.

Because you paint cars my guess is you're familiar with and use a lot of body shop grade and body shop safe compounds and polishes. Nothing wrong with this just make sure by doing some testing that the products you choose to use either,

1. Are formulated and recommended for use with dual action polishers

And/Or

2. Visually appear to work to your expectations upon your inspection after use.

Here's a little article I wrote on this topic. The article is the result of me answering questions for people NOT getting good results when using the Flex 3401 and tracing the ROOT CAUSE of the issue back to the abrasive technology chosen not the tool or the pad.

For Use with Rotary Buffer Only - Read the Directions

For what it's worth... if a person were to read enough of my articles or replies to others questions they will see that I use the below two words a lot when helping others to troubleshoot root causes of paint finishing problems.

abrasive technology

I agree 100% Mike. Fortunately I have most of my supplies provided to me and an organization that wants the best for their customers. With this thread I hope to evaluate what products I need for the best results possible, and then go to my manager with that information. The best way to do that is with my own personal evaluation with multiple tests and results, and with our refinishing products, but not being limited to/by our current polishing and finishing products. Also, I implore all forum members with any experience to post their thoughts and comments as I do this testing. I'm always searching for better advice and information. That's why I'm posting it and that's why I'm here!

-

Super Member

Re: Year Long 3401 Production Review & Rotary Finish Compairson

Originally Posted by Zubair

Flex looks stunning in gloss black.

Thanks! It's actually Lexus 217 in semi-gloss.

-

Super Member

Re: Year Long 3401 Production Review & Rotary Finish Compairson

Subscribed!

Thanks 7PG for sharing your log with us. Very helpful and considerate. I NEVER stop learning.

-

Regular Member

Re: Year Long 3401 Production Review & Rotary Finish Compairson

Subscribed as well. Can't wait to see what this thread has to offer. I too am always trying to lean something new

Similar Threads

-

By Mike Phillips in forum Flex Polishers

Replies: 4

Last Post: 01-26-2024, 10:12 PM

-

By Mike Phillips in forum Flex Polishers

Replies: 4

Last Post: 12-14-2020, 09:38 AM

-

By Mike Phillips in forum Product Reviews by Mike Phillips

Replies: 13

Last Post: 08-03-2020, 11:36 AM

-

By wantboost in forum Auto Detailing 101

Replies: 12

Last Post: 05-12-2017, 11:36 AM

-

By ron.logan in forum Auto Detailing Tools and Accessories

Replies: 22

Last Post: 10-19-2009, 11:01 PM

Members who have read this thread: 1

Members who have read this thread: 1

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

|

| S |

M |

T |

W |

T |

F |

S |

| 31 |

1

|

2

|

3

|

4

|

5

|

6

|

|

7

|

8

|

9

|

10

|

11

|

12

|

13

|

|

14

|

15

|

16

|

17

|

18

|

19

|

20

|

|

21

|

22

|

23

|

24

|

25

|

26

|

27

|

|

28

|

29

|

30

| 1 | 2 | 3 | 4 |

|

Thanks:

Thanks:  Likes:

Likes:  Dislikes:

Dislikes:

Reply With Quote

Reply With Quote

Bookmarks