Thanks: 0

Likes: 0

Dislikes: 0

-

Rotary Polisher Flex 14-2-150

How many individuals on here own the Flex Rotary 14-2-150 ?

And the big question is how is it holding up ?

I have owned Dewalt, Black and Decker, AEG, and Makita Rotary polishes.

I am a boat enthusiast and when you buff a boat you are really beating on any machine that you are using, any machine will heat up, just because of the amount of area you are polishing or compounding.

The most durable machine I have ever used was the EEG rotary, you could really put your weight on it and it would just keep going. The company is no longer in business.

Now I use the Makita no complaints nice machine.

I am a tool junkie and have been looking at the Flex machine for some time now.

I am dying to acquire the new Flex but just wanted some input form guys who actually own them .

Thank you in advance for the replies.

-

Re: Rotary Polisher Flex 14-2-150

I have not had a single PE14 break since we started carrying them and AG was the first to get them. Max has the #1 Production Unit and I have the #2 Production Unit.

The most important thing to keep in mind is when comparing the Flex PE14 to these other rotary buffers you mentioned is the Flex PE14 is a lightweight, compact rotary buffer. These others rotary buffers are Full Size rotary buffers.

From my review here,

Bumblebee - Testing out the NEW DeWALT DWP849X

Post #45 but I would recommend reading through the entire thread as it's jam packed with tons of good information plus a really cool car.

Originally Posted by kronos

Very nice review Mike. That Flex sure does have plenty of good things going for it. The only real negative seems to be the high initial cost.

Quality never costs money it makes money...

Originally Posted by kronos

The one remaining unanswered question I have is, can it be used for high volume paint correction work? The DeWalt looks heavy duty, like it was made for high volume work. Can the same be said of the Flex?

According to Flex the answer is yes. They state that up to an 8" diameter pad can be used with the Flex PE14 but I prefer to stay a little smaller especially for wool pads.

More reciprocating mass creates more torque

My personal thoughts are that if you're going to be buffing out sanding marks all day long or removing oxidation from large boats all day long then a full size rotary buffer would be a better choice.

The gears are bigger in size as are the rest of the components in a full size rotary buffer and I think having more reciprocating mass creates more torque and this is something you would want if you're going to be doing heavy compounding and polishing with full size pads, (8" and larger), 6 days a week.

Originally Posted by Wills.WindowsAndWheels

It does look beautiful indeed. No way i could swing that kinda cash for a rotary right now but its nice to have some input as to a comparison of the 2 polishers.

Quick question...what major differences do you see between the PE and the 3403 flex rotary?

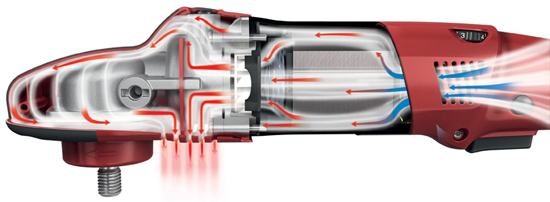

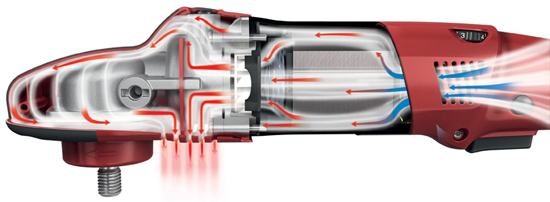

First major difference is the new Flex PE14 has the design that flushes the tool with air to help the tool run cooler.

More information and a video on this page,

The New FLEX PE14-2-150 Rotary Buffer

Originally Posted by Wills.WindowsAndWheels

Also to those who were interested in the 3" pads...AG does sell some...they are made by Griots...of course!

Correct and these work well too. You can see them in action here,

Pictures + Video of 1932 Ford Highboy Extreme Makeover

The 3" pads I'm using are some prototypes...

Originally Posted by Wills.WindowsAndWheels

I must say that detailing cart looks super sweet....another wish list item...grrr....i wont buy it till i finally have a stationary place to do my detailing...too bulky for mobile detailing..im 25..i can still lean over to clean my pads LOL.

The cart is nice, it makes using the pad washer a lot easier plus gives you plenty of storage space for other related tools.

After about 6 hours of running both rotary buffers here's what I think, the new DeWALT is a great rotary buffer especially for the price. The 600 RPM low range is the most valuable feature. I also really like the rubber bumpers on the back side that enable you to set it down on a polished fender or hood without scratching the paint.

Apples to Oranges

Comparing the Flex PE14 to any of the full size DeWALT rotary buffers, or the Makita, or any other brand of full size rotary buffers is like comparing apples to oranges in that the Flex PE14 is a true compact rotary buffer and falls into the Compact Size category, while the DeWALT DWP849X falls into the Full Size category for rotary buffers.

Makita 9227C vs DeWALT DWP849X

A better comparison would be to compare the Makita 9227C with the DeWALT DWP849X as they are much more similar and my guess is that DeWALT introduced this new model to compete against the Makita rotary buffer. Both of these buffers, the Makita or the DeWALT would be great choices. I've always been a fan of Makita rotary buffers if for no other reason because I used one for years until it finally wore out having purchased it new in 1988.

The best of both worlds

In a perfect world a person would have at least two rotary buffers, a full size working dog for doing all of the grunt work and a compact, light-weight rotary buffer for when you need to dosurgical precision work. This way you can use the one that best fits the job at hand.

The compact size and low weight of the Flex PE14 plus the 600 RPM range are the features I'm most attracted to. It's light weight and small size make it really easy to control when doing intricate work. Perhaps we'll see the introduction of other compact, lightweight rotary buffers into the future.

After the compounding the upper half of the 1949 Sedan Delivery, I just switched over to the Flex PE14 due to the light weight and compact size features. I could have used either for the rest of the job by my preference was for the easiest tool to work with as this streetrod has a lot of real-estate to buff.

Here's some pictures to show relative sizes...

The two Flex rotary buffers on the left are in the Compact category while the other 4 rotary buffers are in the Full Size category. Comparing the compacts with the full size rotary buffers can be done but it trends towards the comparing applies to oranges analogy as in person and in use you can tell right away when you switch from a full size to a compact or visa-versa.

The new DeWALT DWP849X is wider and more bulky like the other full size rotary buffers in these pictures.

You can that the Flex is more narrow from top to bottom...

-

Re: Rotary Polisher Flex 14-2-150

Here's the car and this was a rotary buffer only buff out...

-

Re: Rotary Polisher Flex 14-2-150

On the topic of overheating, I've had them overheat on me and when this happens, unlike other rotary buffers the Flex PE14 has a 7-Function Microprocessor Circuit inside of it and when a certain temperature level is reached it turns the tool off so no damage occurs.

You could read that to mean that if other rotary buffers overheat they continue operating and I guess that means damage can occur?

The Flex PE14 is the first rotary buffer I grab for most projects, especially anytime I'm doing what I call Surgical Buffing, or as some like to say, Precision Buffing.

Here's the big picture...

With a smaller body for the tool, that is without the bulk and weight of a full size rotary buffer, it's easier to get into tighter areas, buff out thinner panels, have more control when buffing out intricate sections or components.

Because it's lightweight, it doesn't tax your muscles as much when doing surgical buffing and this is important as it helps you from making a mistake. Here's some articles on this topic,

Surgical Buffing

Trend: Backing Plate Extensions for Surgical Precision Buffing

Surgical Precision Buffing Tools

The only way to fly on the stainless steel on an old Buick...

Here's Andre using a 4" wool cutting pad for the thin panels on this old boat...

I think this was being done to this old Porsche...

Flex PE 14 Rotary Buffer using Pinnacle Advanced Swirl Remover on this old Ford

So when viewed from the right perspective, the Flex PE14 is a great tool to have along side a full size rotary buffer and then you can pick the best tool for the job.

-

Re: Rotary Polisher Flex 14-2-150

Here's a car I sanded down twice and then buffed out twice using the Flex PE14, we captured the entire thing using a GoPro camera but as of yet, Yancy has not had time to get it loaded onto our YouTube Channel.

Time-Lapse Video: Wetsand, Cut and Buff 1964 Malibu

I started the actual sanding around 10:00am this morning and have about 75% of the car done and all the way through to wax. Just have the passenger side vertical panels left to do.

Sanded with 3M Trizact #3000 then #5000 then compounded, polished twice and then machine waxed.

The GoPro is set up to take a picture ever minute. I 'll finish the passenger side this weekend and sometime next week Yancy will have the video on YouTube.

That I know of, this is the first time a complete wetsand, cut and buff all the way through to wax has ever been captured via time-lapse.

While buffing out my sanding marks, towards the end of each time, (I buffed it twice, 1 time to compound, 1 time to polish), I had the Flex PE14 turn off due to overheating.

So that's me buffing hard, on a full size American muscle car and at the last panel after solid buffing as I never stopped for breaks when I buffed this car out, it did get hot enough to shut off.

That's a lot of buffing and most people I know take more breaks than I do. A lot more. Of course, I simple grabbed another Flex PE14, swapped my same backing plate and pad over to it and continued buffing because I was on film. If the video ever gets posted you'll see me switching buffers.

I only use 7" and 7.5" buffing pads on the Flex when using wool pads and stick to 6.5" pads or smaller when using foam.

I whole heartedly recommend the Flex PE14 to anyone looking for a quality tool but keep in mind which class of rotary buffer it is and that's a lightweight, compact rotary buffer. Comparing it to a full size DeWALT, Makita, 3M, Milwaukee is comparing apples to oranges.

-

Re: Rotary Polisher Flex 14-2-150

Not sure if you've read this thread yet...

24' Pro-Line Boat - Extreme Marine Makeover - Oxidation Removal!

But this is a big boat in HORRIBLE condition. You'll see a wide variety of rotary buffers being used including the Flex PE14. I used the Flex PE14 most of the time I was buffing but when I came across a few sections on the black gel-coat hull that had really bad oxidation and water staining, I grabbed the DeWalt and as I posted in the write-up and had someone take my picture to make the point...

I leaned into the rotary buffer....

And it got HOT!

So hot if I moved my hand off the rubber overmold the metal head would have been too hot to touch.

Click on the thread, look at the pictures... you'll see...

-

Re: Rotary Polisher Flex 14-2-150

Mr.Mike

WOW, I must say that was an impressive review.

After reading all that I realize how much I do not know.

I guess I have no choice but to buy a new Flex Rotary Polisher !

Thank you for taking the time to reply.

-

Super Member

Re: Rotary Polisher Flex 14-2-150

When I first purchased and began using the PE-14-150 it got really hot on me. My first time working with it on a really heavy correction job, Stubborn as 5 goats. it got too hot to handle before getting through the first half of the job.

I have to say though, that I was pushing onward through the job pretty hard as I normally do. I wanted to know if it would stack up to the demands that I personally put on the tools I own. I had a 7" foam pad on the PE-14-150 and was attempting to level out some pretty bad paint defects from general neglect as well as hoof scratches/scuffs from the 5 goats that had been climbing all over the poor car while my buddy Pete was out of town on business.

I really believe (looking back in hind sight) that the brushes weren't fully seated to the armature in the PE-14-150 when I worked on the goat clobbered Honda Accord so that added to the over heating problem. There was smoke coming out of the cooling vents so I switched over to my Makita for the rest of the job.

In my opinion and experience the PE-14-150 is a very smooth running, well balanced and comfortable rotary polisher with slight limitations. It is great for running 5" foam pads or smaller, and can handle any size wool pad for the long haul as long as you allow the wool and compound to do the work. If you start leaning into the tool it gets pretty darned hot.

I ended up selling mine to "BostonDetails" and he loves it. My shop sees too much grunge work and heavy paint correction and the PE-14-150 stayed in the cabinet for the most part. Sometimes I wish I still had it for the more delicate work but the Makita does fine for that too.

If I had it to do over (in my particular setting) I'd have taken the money I spent on the PE-14-150, added a few more dollars and bought two Dewalt 849X units.

Overall I say it's a very nice machine that will serve you well if you don't tax it too hard. I'd suggest having a heavy duty rotary on hand if you're running a business.

-

Re: Rotary Polisher Flex 14-2-150

Originally Posted by tuscarora dave

Overall I say it's a very nice machine that will serve you well if you don't tax it too hard. I'd suggest having a heavy duty rotary on hand if you're running a business.

Good summary Dave.

I like having access to both styles, full size and compact size and then choosing the right tool for the job.

For guys looking at either the Makita or the DeWALT, check this out..

DeWALT DWP849X vs Makita 9227C Rotary Buffers

-

Re: Rotary Polisher Flex 14-2-150

Originally Posted by Big boys toys

Mr.Mike

WOW, I must say that was an impressive review.

After reading all that I realize how much I do not know.

I guess I have no choice but to buy a new Flex Rotary Polisher !

Thank you for taking the time to reply.

You're welcome and thanks....

I cut my teeth on a Makita Rotary Buffer, in fact there was time in my life when I fed myself and paid the bills with only my Makita.

I still have my original Makita, it's sitting here next to me in my office. I buffed out a LOT of cars over the decades with it so it has a lot of sentimental value to me.

Similar Threads

-

By Mike Phillips in forum Product Reviews by Mike Phillips

Replies: 0

Last Post: 12-10-2019, 02:50 PM

-

By Mike Phillips in forum Ask your detailing questions!

Replies: 2

Last Post: 08-20-2018, 08:00 AM

-

By Mike Phillips in forum Ask your detailing questions!

Replies: 10

Last Post: 09-08-2015, 11:48 AM

-

By RobRabbit2.5 in forum Off-Topic

Replies: 21

Last Post: 11-10-2014, 03:32 PM

-

By Pontiac G8 in forum Flex Polishers

Replies: 10

Last Post: 03-09-2014, 07:37 AM

Members who have read this thread: 0

Members who have read this thread: 0

There are no members to list at the moment.

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

|

| S |

M |

T |

W |

T |

F |

S |

| 31 |

1

|

2

|

3

|

4

|

5

|

6

|

|

7

|

8

|

9

|

10

|

11

|

12

|

13

|

|

14

|

15

|

16

|

17

|

18

|

19

|

20

|

|

21

|

22

|

23

|

24

|

25

|

26

|

27

|

|

28

|

29

|

30

| 1 | 2 | 3 | 4 |

|

Thanks:

Thanks:  Likes:

Likes:  Dislikes:

Dislikes:

Reply With Quote

Reply With Quote

Bookmarks