Thanks: 0

Likes: 0

Dislikes: 0

-

What's the issue here? Part Deux

Some of you may remember this thread and my all-out rage against my poor polisher. Grab a beverage, sit back, and relax, because this is long. You have been warned.

First, I would like to thank everyone who took an angry, frustrated starting post and proceeded to offer suggestions and ideas to help me out. Once again, thank you. Not only for the help, but being patient with me.

However, once in a while there are random acts of kindness that go unparalleled. I received a PM from Richard (aka rwright) saying he wanted to send me a sample of some products. Ok, I thought. Maybe there's some new Duragloss compound that cuts like nobody's business and finishes well. Boy was I wrong!

Here's what arrived via Santa dressed in brown:

- 4 Tangerine 7/8" Pads

- 4 Cyan 7/8" HT Pads

- 2 MF Cutting Discs

- 16 oz. D300

- 1 LC 5" BP

- 1 W67DA BP

No, he did not send me a used Tangerine pad. More on that later.

Suffice it to say, when the package came I was at a complete loss of words. I couldn't believe someone would do such a favor to somebody they didn't even know! Thank you, Richard.

Now, on to why I was so frustrated. I was working on polishing my Grand Prix, and even small sections were literally taking me hours.

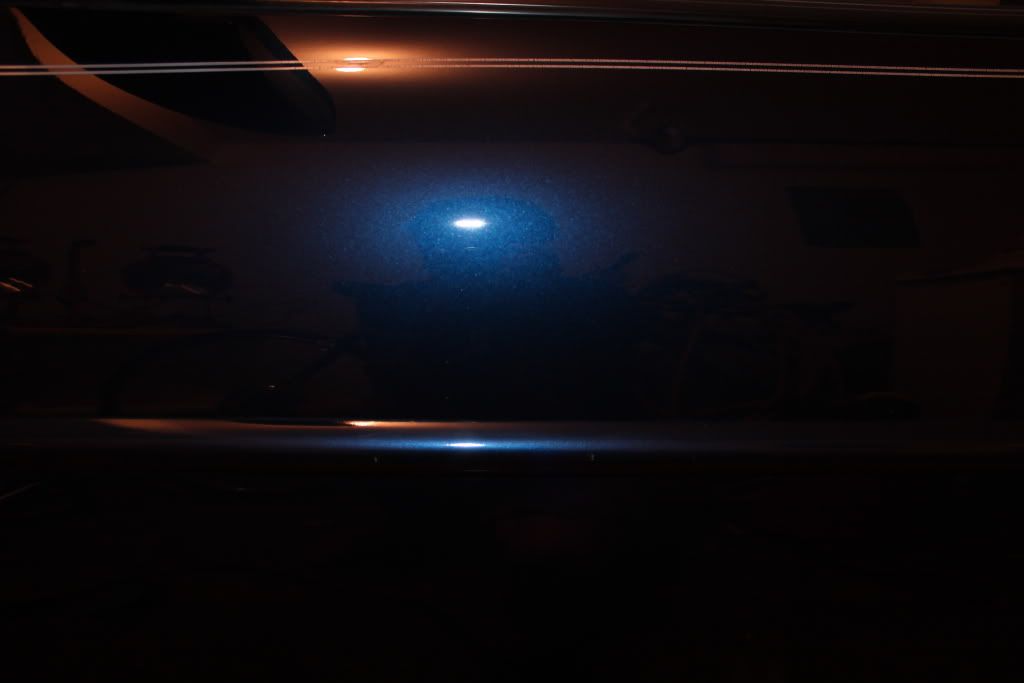

Here is a small sample of what I was working with:

1.

What should I do? I threw my Edge DA adapter in the trash (just kidding!) and put the W67DA on my 7424. On went the MF cutting disc.

Observations: I swore my self-centering pads would be the greatest thing since sliced bread. I realize now it's not that hard to change backing plates, and even easier to center a pad on one!

Back to the story. . .

I broke out the D300 and started priming the pad. Wow, cinnamon! This stuff smell so good I want to eat it! (So does my dog. . .) Once the pad was primed I started polishing.

What can you do in 30 seconds of polishing with new technology?

This!!

2.

The speed, finish, and ease of use of the MF systems astounded me. From this moment forward I was regretting not buying it the instant it became available. I continued polishing, and here's my test section after:

3.

4.

Flash pictures:

5. (polished side)

6. (unpolished side before finishing section)

A little more detail in that area:

All of the above pictures are after 1 pass of MF/D300 on speed 4 of a 1st gen PC, with no finish polising.

Observations:

Polisher Ease of Use- Absolutely incredible. The polisher was vibrating the pad, not me! Moderate pressure did not stop the pad from rotating, and the pad conformed very well to the body contours. I was even able to "edge" the pad into body lines and polish those!

Compound- D300 showed only the slightest signs of dusting. Otherwise, this stuff definitely shows how it was designed for the MF disc. It absorbed well when priming, yet allowed the disc to glide smoothly over the paint.

Defect Removal- Outstanding. Only the deeper RIDS remained, and on a DD I will live with those. Also, see how in picture 1 there is damage left from where I removed the emblem? Try and find that in the finished pics.

Finish- The haze left by this compound only shows itself well in picture 3. It was more evident in person, but I can't emphasize enough how much better than the before condition it looked.

Pad Cleaning- These MF pads clean up very well, and easily! In fact, I got a little aggressive when polishing over my pinstripe, and some gray, gummy gunk was transferred to the pad. I was afraid this would not wash out, and damage the fibers. It washed out (by hand) perfectly with no fiber damage!

Here is a picture of the MF pads. One has been used and cleaned, the other is brand new.

8.

Now back to the story. . .

Today I tried finishing up the door. MF/205? Nope, left hazing (surprised me). So I change to the LC BP and put on a Tangerine HT pad and primed it with 205.

Once again, wow! The HT really keeps almost all of the polish between the pad and the paint! M205 worked better and easier than it ever did with my Edge blue polishing pad. It was obvious the HT was keeping a nice thin film of polish between the pad and the paint.

This part surprised me: Considering the stiffness of the pad, I assumed it would be difficult to keep the pad rotating. However, the exact opposite was true. The thinness combined with the stiffness of the pad kept it from absorbing the polisher's energy, instead transferring it to the paint. In short: Only very heavy pressure could stop the pad from rotating on a relatively flat panel. (Once again, I remind you I am using a 1st gen. PC.) This allowed me to use enough pressure to conform the pad to body curves without stopping the pad from spinning.

The Tang. pad finished incredibly well. Cleanup was a little difficult, however. Hence the residue seen in the first picture.

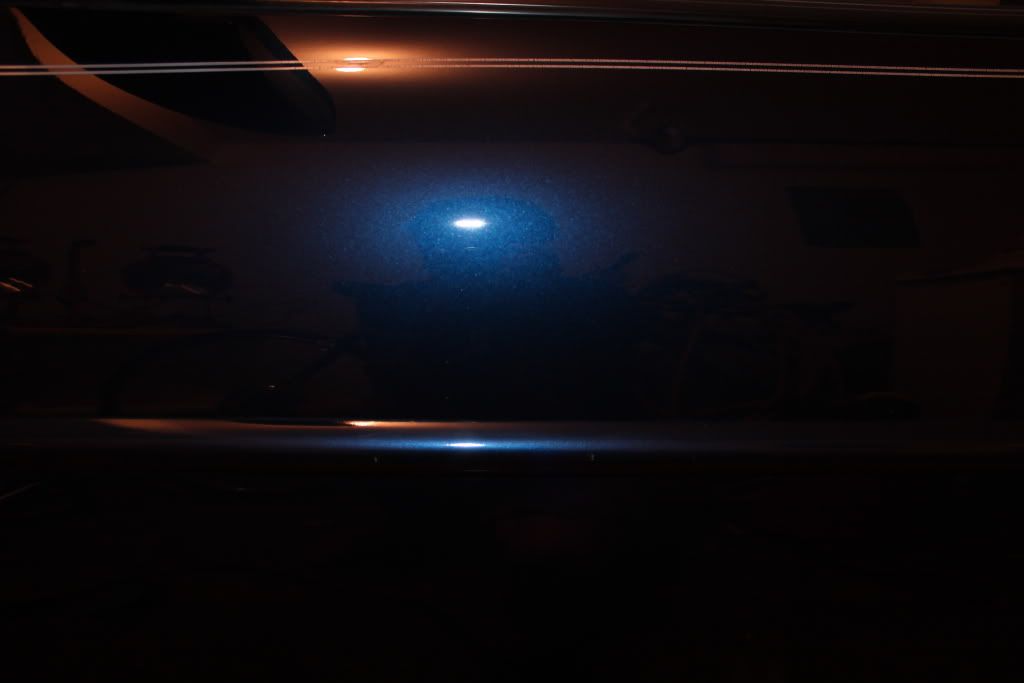

Are you ready for after pics?? There is no lsp in these pictures.

9. Halogens

10. Flash

Please forgive the fingerprint in picture 9. I used that as a focus point because even in manual focus I couldn't focus on the paint!

Final Thoughts

Considering what I was used to, the new products are incredible. The total time invested on this door panel for a 2-step polish was maybe 30 minutes. Simply compounding this door using my traditional method (Edge Green + M105) would have taken me at least 45 minutes.

Also, look at picture 9. Do you see that POP? I have never been able to achieve that before with my old products.

My PC7424 is now a much more capable, easy to use machine.

This is all brought to you by Richard and his generosity. Thanks buddy!

-

Super Member

Re: What's the issue here? Part Deux

WWWOOOOOWWWWWW!!!! That was very awesome of him. And man...I wish I had the same luck with the Meg's MF. I want to try the 5" pads on a harder paint.

Alex

...."Do the right thing...even when no one is looking"

-

Super Member

That is why I love this forum. Such great people. One never feels alone here.

-

Super Member

Re: What's the issue here? Part Deux

Nice write up! And very nice of Richard for sending you that stuff.  I always wanted to try the MF system and now I'm probably going get it next sale. I always wanted to try the MF system and now I'm probably going get it next sale.

I used the HT pads at work and never really had any problems with them. I find them a lot more aggressive then orange/white flats. But they finish down real nice.

-

Super Member

Re: What's the issue here? Part Deux

Perfect example of how awesome this community is! Also another happy user of the Meguiars MF System! I can't tell you how many hours the MF cutting disc with D300 has saved me!

-

Super Member

Re: What's the issue here? Part Deux

It seems as if Richard was going to make you a believer no matter what! lol.

Kudos, Rich...that's a more than generous thing to do.

-

Super Member

Re: What's the issue here? Part Deux

Looks great Kevin! We new you could do it!

Richard is a stand up guy......

Tim "I have done so much with so little for so long. Now I can do anything with nothing"

-

Re: What's the issue here? Part Deux

Like I said, I just didn't want you to give up on the machine. It's amazing what the right product combo can achieve huh? The paint turned out amazing and I'm glad it worked out better for you. Something to try and I mentioned in pm, use M105 on the mf pad to see if it cuts some of the RIDS. You may have to go a little more aggressive but like you said it is a daily driver and some stuff you just have to live with. Now save up and pick up a more powerful machine!

"Challenge yourself to live a better tomorrow than you did yesterday"

-

Re: What's the issue here? Part Deux

Originally Posted by aerogt01

However, once in a while there are random acts of kindness that go unparalleled. I received a PM from Richard (aka rwright) saying he wanted to send me a sample of some products.

- 4 Tangerine 7/8" Pads

- 4 Cyan 7/8" HT Pads

- 2 MF Cutting Discs

- 16 oz. D300

- 1 LC 5" BP

- 1 W67DA BP

No, he did not send me a used Tangerine pad. More on that later.

Suffice it to say, when the package came I was at a complete loss of words. I couldn't believe someone would do such a favor to somebody they didn't even know! Thank you, Richard.

Incredible act of kindness. Very impressive Richard.

Originally Posted by aerogt01

Once again, wow! The HT really keeps almost all of the polish between the pad and the paint! M205 worked better and easier than it ever did with my Edge blue polishing pad.

Closed cell foam = Non-Reticulated foam

From page 55 of my book...

Closed Cell Foam mans the cell wall structure is closed with the membranes intact. This makes the foam non-porous, and while it's not impossible for air and liquids to flow through it, it is more difficult.

Originally Posted by aerogt01

This part surprised me: Considering the stiffness of the pad, I assumed it would be difficult to keep the pad rotating. However, the exact opposite was true. The thinness combined with the stiffness of the pad kept it from absorbing the polisher's energy, instead transferring it to the paint.

Thin is in...

This was posted over a year ago here,

Thin is in... New Lake Country Hydro-Tech Low Profile 5 1/2 x 7/8 Inch Foam Pads

And on page 54 of my book...

The thinner the backing plate, the more successfully the energy and the oscillating pattern from the tool will be transferred to the buffing pad. This is what you want anytime you're trying to remove below surface defects like swirls, scratches and water spots.

Originally Posted by aerogt01

In short: Only very heavy pressure could stop the pad from rotating on a relatively flat panel. (Once again, I remind you I am using a 1st gen. PC.) This allowed me to use enough pressure to conform the pad to body curves without stopping the pad from spinning.

My PC7424 is now a much more capable, easy to use machine.

Dang this was written over a year ago now too...

The short how-to guide for using a DA Polisher

How to maximize the ability of the 1st Generation Porter Cable Dual Action Polishers

Originally Posted by aerogt01

This is all brought to you by Richard and his generosity. Thanks buddy!

Incredible follow-up story to your original post on your frustration with your first generation PC. As everyone on this forum has seen, the trend for pads both foam and fiber, for the PC style tools has been for thinner pads for the primary reason in that it's easier for these types of tools to maintain pad rotation under pressure.

The HT pads you're using are 7/8" thick and the Microfiber and Surbuf pads on the market now are even thinner. I don't expect this trend to reverse anytime into the future but do expect to see more pads and products introduced to leverage the safety feature and ease of use with these types of tools.

As for Richards over the top act of kindness... one word... impressive...

It makes me personally very proud of the people that make up this forum community. Thank you so much for your follow-up thread to the original here,

What's the issue here?

-

Super Member

Re: What's the issue here? Part Deux

That is awesome! Glad you were able to get the issues worked out. It looks like my next order will contain the Megs MF kit as well as some HT thin pads. I feel like I am in the stone age with my LC CCS pads now lol.

Time to add to the arsenal!

Similar Threads

-

By ReflectiveAuto in forum Auto Detailing 101

Replies: 55

Last Post: 07-09-2016, 10:01 PM

-

By Dr_Pain in forum Product Reviews

Replies: 15

Last Post: 09-21-2014, 10:38 PM

-

By eShine Canada in forum Show N' Shine

Replies: 9

Last Post: 04-01-2014, 12:12 AM

-

By sportscarhiatus in forum Auto Detailing 101

Replies: 15

Last Post: 06-14-2012, 02:48 PM

-

By orngez in forum Show N' Shine

Replies: 18

Last Post: 04-04-2007, 09:22 PM

Members who have read this thread: 0

Members who have read this thread: 0

There are no members to list at the moment.

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

|

| S |

M |

T |

W |

T |

F |

S |

| 26 | 27 | 28 | 29 | 30 | 31 |

1

|

|

2

|

3

|

4

|

5

|

6

|

7

|

8

|

|

9

|

10

|

11

|

12

|

13

|

14

|

15

|

|

16

|

17

|

18

|

19

|

20

|

21

|

22

|

|

23

|

24

|

25

|

26

|

27

|

28

|

29

|

|

30

| 1 | 2 | 3 | 4 | 5 | 6 |

|

Thanks:

Thanks:  Likes:

Likes:  Dislikes:

Dislikes:

Reply With Quote

Reply With Quote I always wanted to try the MF system and now I'm probably going get it next sale.

I always wanted to try the MF system and now I'm probably going get it next sale.

Bookmarks