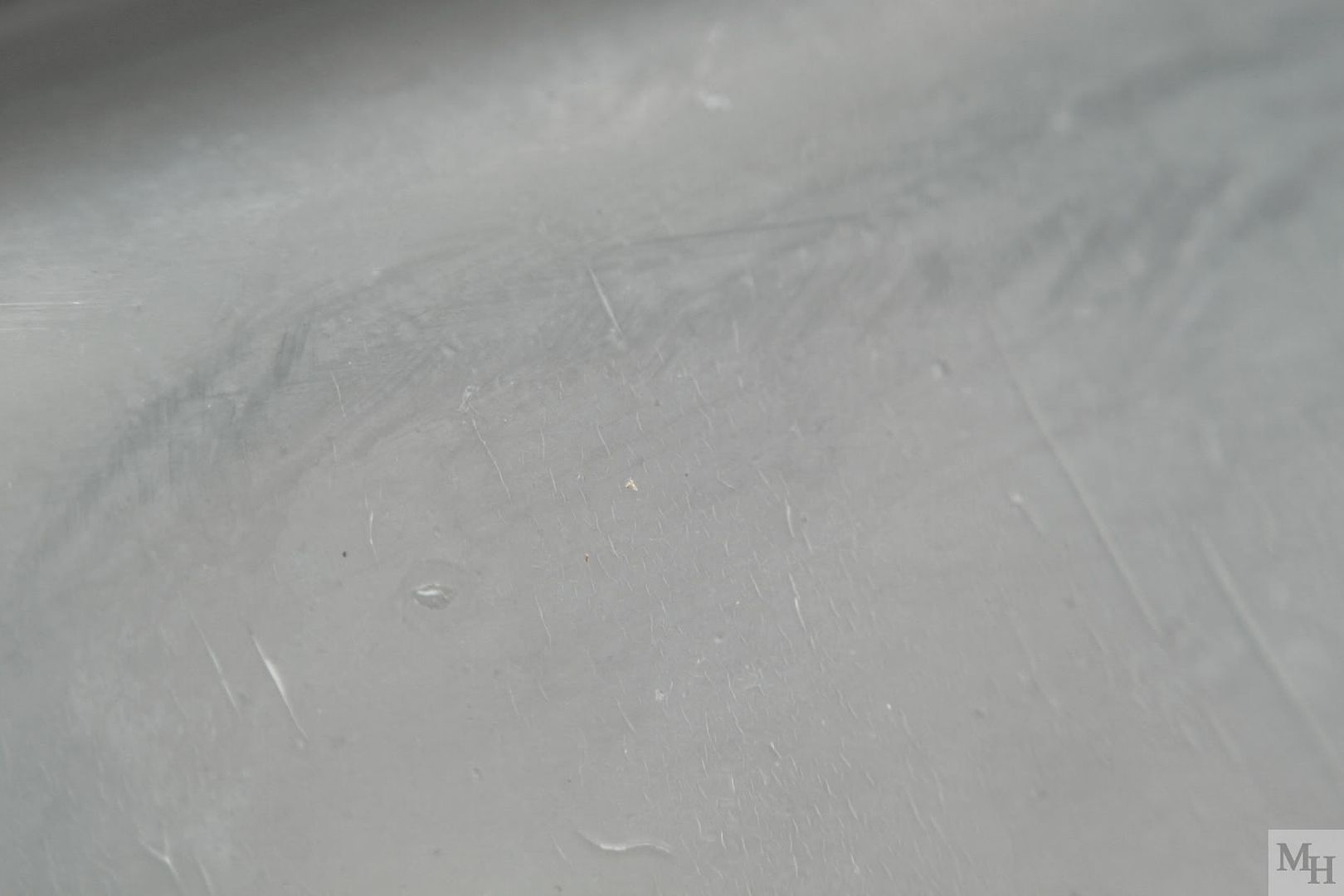

We use 1996 Ford Taurus as our standard test headlight because they are really bad, being 16 years old.

In reality you can restore just about any headlight to like new regardless of condition if the following conditions are met:

1. No water or moisture in the headlight

2. No holes or through cracks

3. You can meet your customer's expectations and budget

4. Base polycarbonate has not been damaged by previous butchering

The procedure in theory is simple:

1. Remove the old protective coating

2. Replace it with a new protective coating

Some require sanding to remove the old coating but most do not. The key is applying a new coating that will last. Most retail coatings on the market are temporary and about equal to what you might apply to paint. Some are great sealers but little or no UV protection and very thin.

For good UV protection and sealing against moisture you need:

Something with good UV blocking or absorbing ability. Wax does this but it is too thin and not permanent.

Something thick, The thicker the coating, the more UV it can block.

Something permanent. Rules out waxes and many proprietary compounds.

Something that can be used in the field (no spraying, no UV curing, no pneumatic tools required, etc.).

I see many are using the spar varnish/mineral spirits method with varying results.

I wouldn't use this procedure if you are charging money. There are many professional coatings available specifically designed to protect headlights from UV.

When you analyze the price of coatings applied to headlights, it might be 25 cents for spar/ms vs. 1.00 for a professional coating. Is long term reliability and customer satisfaction worth risking to save 75 cents?

Here is two videos showing restoration of 16 year old headlights using two different processes:

Water based

http://youtu.be/_hzcelTUvJo

Solvent based

https://www.youtube.com/watch?v=oBtl68SlcBc&list=HL1340757828&feature=mh_lolz

ray6