Thanks: 0

Likes: 0

Dislikes: 0

-

-

-

Super Member

Re: Top Secret Pictures – How Rupes Bigfoot Polishers are made!

That's pretty cool for sure, thanks for the behind the scenes tour. Looks like a top notch run facility. Thanks for posting and sharing.

-

Super Member

Re: Top Secret Pictures – How Rupes Bigfoot Polishers are made!

Awesome tour, thanks for capturing the moments and sharing them here.

Just started using my Rupes 21 some weeks ago, proud owner here, even prouder now.

My regards to all Rupes facility members.

“Nature is pleased with simplicity. And nature is no dummy”

― Isaac Newton

-

Super Member

Re: Top Secret Pictures – How Rupes Bigfoot Polishers are made!

Impressive to see where my DA's come from. Thanks for the tour.

-

Junior Member

Re: Top Secret Pictures – How Rupes Bigfoot Polishers are made!

Very nice looking plant. It is so nice to get a factory tour.

-

Super Member

Re: Top Secret Pictures – How Rupes Bigfoot Polishers are made!

Every time I look at these pictures it clearly shows the quality manufacturing processes and products Rupes uses and why I have three of their machines. I'm sure that all the Chinese knock offs aren't made with parts that even come close to the quality of Rupes parts. All you have to do is take one look at Rupes counter balance and their gears and that pretty much tells the story.

2013 Genesis Coupe 3.8 Track Edition

2015 Hyundai Sonata Limited, 2016 Pearl White Nissan Altima SR

2019 Nissan Rogue SL

-

Re: Top Secret Pictures – How Rupes Bigfoot Polishers are made!

Mike, Thanks a lot for the great tour and pictures. It's the closest we will ever get to being there in person.

A major part of my life has been spent in electronics. I went to school when I was a young man full time and had an electronics repair shop many years ago. The armatures being ground for balance purposes tells a lot of the quality that Rupes is trying achieve. I know a lot about this subject and I can see the quality in their products. Their windings in the armatures and field coils are top notch and very neat and solid. Bearings and shafts are neat and clean with no trash to cause premature failure.

Some very fine machining processes are in place and quality control. My father was a quality control man at TRW many years ago and it is very important in turning out a perfectly balanced machine. Some day soon I will get one of these machines in my hands to try out.

Thanks again for a once in a lifetime virtual tour.

-

Re: Top Secret Pictures – How Rupes Bigfoot Polishers are made!

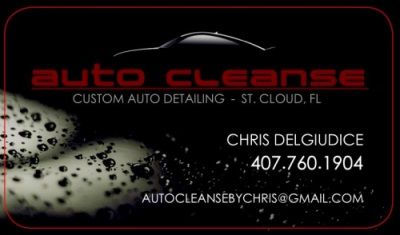

Originally Posted by Chris@AutoCleanse

That's pretty cool for sure, thanks for the behind the scenes tour. Looks like a top notch run facility.

Thanks for posting and sharing.

You're welcome. At the time, I was the first person they ever let take pictures inside the plant and share them on a public forum.

Originally Posted by Tato

Awesome tour, thanks for capturing the moments and sharing them here.

You're welcome.

Originally Posted by custmsprty

Every time I look at these pictures it clearly shows the quality manufacturing processes and products Rupes uses and why I have three of their machines.

I have a background in process control in manufacturing and both RUPES and FLEX have top notch manufacturing plants. (toured Flex in 2011)

Originally Posted by Garyhw48

Mike, Thanks a lot for the great tour and pictures. It's the closest we will ever get to being there in person.

A major part of my life has been spent in electronics. I went to school when I was a young man full time and had an electronics repair shop many years ago.

The armatures being ground for balance purposes tells a lot of the quality that Rupes is trying achieve.

I know a lot about this subject and I can see the quality in their products. Their windings in the armatures and field coils are top notch and very neat and solid. Bearings and shafts are neat and clean with no trash to cause premature failure.

Some very fine machining processes are in place and quality control. My father was a quality control man at TRW many years ago and it is very important in turning out a perfectly balanced machine. Some day soon I will get one of these machines in my hands to try out.

Thanks again for a once in a lifetime virtual tour.

Keen observations Gary and that's why I took those particular pictures.

-

Re: Top Secret Pictures – How Rupes Bigfoot Polishers are made!

will the ccs pads work on the 15 mark2?

Similar Threads

-

By Mike Phillips in forum How to articles

Replies: 0

Last Post: 08-30-2017, 02:53 PM

-

By kifft in forum RUPES BigFoot Oribital Polishers

Replies: 1

Last Post: 07-29-2017, 07:57 PM

-

By Mike Phillips in forum Ask your detailing questions!

Replies: 15

Last Post: 11-22-2015, 10:00 PM

-

By Harry Da Hamster in forum Auto Detailing 101

Replies: 66

Last Post: 06-25-2015, 12:42 PM

-

By Mike Phillips in forum Ask your detailing questions!

Replies: 12

Last Post: 02-11-2013, 01:43 PM

Members who have read this thread: 0

Members who have read this thread: 0

There are no members to list at the moment.

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

|

| S |

M |

T |

W |

T |

F |

S |

| 31 |

1

|

2

|

3

|

4

|

5

|

6

|

|

7

|

8

|

9

|

10

|

11

|

12

|

13

|

|

14

|

15

|

16

|

17

|

18

|

19

|

20

|

|

21

|

22

|

23

|

24

|

25

|

26

|

27

|

|

28

|

29

|

30

| 1 | 2 | 3 | 4 |

|

Thanks:

Thanks:  Likes:

Likes:  Dislikes:

Dislikes:

Reply With Quote

Reply With Quote

Bookmarks