Thanks: 0

Likes: 0

Dislikes: 0

-

Super Member

-

Super Member

Re: Year Long 3401 Production Review & Rotary Finish Compairson

That is a phenomenal finish on that new paint! I'm excited for you to continue too.

-

Super Member

Re: Year Long 3401 Production Review & Rotary Finish Compairson

Perfect timing for this thread for me. I'm actually starting to use a rotary more and more. I'm not a pro, but have used several different compounds and polishes on both machines. I've got the 3D rubbing compound and finishing polish on the way. I'm really in seeing your results. If you want to try some different products without shelling out hundreds of dollars I would be more than happy to send you some 6 or 8 oz samples of some polishes and compounds to try.

-

Super Member

Re: Year Long 3401 Production Review & Rotary Finish Compairson

Originally Posted by Puckman

That is a phenomenal finish on that new paint! I'm excited for you to continue too.

Thanks! New paint can be fun when you're the one controlling the mills of the CC and it's never seen the light of day!

Originally Posted by DaveT435

Perfect timing for this thread for me. I'm actually starting to use a rotary more and more. I'm not a pro, but have used several different compounds and polishes on both machines. I've got the 3D rubbing compound and finishing polish on the way. I'm really in seeing your results. If you want to try some different products without shelling out hundreds of dollars I would be more than happy to send you some 6 or 8 oz samples of some polishes and compounds to try.

I may take you up on that offer. I'm sure we could find and equal trade that could benefit the both of us. I know Mike P has written many many articles about rotary polishing and I know I haven't read through them all but hopefully during this I can share some new tips and tricks some may have never considered. If someone gave me a tip, and a cow and firecrackers were involved, and it resulted in a better finish, I'd try it!

-

Super Member

Re: Year Long 3401 Production Review & Rotary Finish Compairson

Originally Posted by Mike.Phillips@Autogeek

To 7PaintGuns,

As you know, having the right tool and pads is only part of the equation. The most important factor in my opinion is to have the best abrasive technology. This is vitally important when it comes to finishing with a dual action polisher otherwise you'll leave tiny scratches in the paint from the abrasive technology.

These tiny scratches are called,

DA Haze (dual action polisher haze)

Tick Marks (a term coined by Meguiar's chemists)

Micro-marring (general term for the scouring appearance caused by low quality abrasive technology used with orbital polishers)

All three of these terms describe the same scratch pattern caused by low quality abrasive technology when used with dual action orbital polishers.

There are other things that cause scratch patterns when using dual action polishers like the pad but keep in mind it's the ABRASIVES that come into contact with the paint surface FIRST not the pad.

Note: Holograms is a term to describe a very specific scratch pattern inflicted into paint by the misuse of a rotary buffer.

Because you paint cars my guess is you're familiar with and use a lot of body shop grade and body shop safe compounds and polishes. Nothing wrong with this just make sure by doing some testing that the products you choose to use either,

1. Are formulated and recommended for use with dual action polishers

And/Or

2. Visually appear to work to your expectations upon your inspection after use.

Here's a little article I wrote on this topic. The article is the result of me answering questions for people NOT getting good results when using the Flex 3401 and tracing the ROOT CAUSE of the issue back to the abrasive technology chosen not the tool or the pad.

For Use with Rotary Buffer Only - Read the Directions

For what it's worth... if a person were to read enough of my articles or replies to others questions they will see that I use the below two words a lot when helping others to troubleshoot root causes of paint finishing problems.

abrasive technology

I'm a bit confused, is DA haze/ micro marring a normal part of corrections or is something wrong in the process? I was taught that haze was normal due to the aggressiveness of the compound/ pad. Just follow up with a polish to eliminate the haze. Should I be finishing down haze free on my cutting step? I don't get haze all the time depends on the paint but I just polish it out

-

Super Member

Re: Year Long 3401 Production Review & Rotary Finish Compairson

Originally Posted by 7PaintGuns

Thanks! New paint can be fun when you're the one controlling the mills of the CC and it's never seen the light of day!

I may take you up on that offer. I'm sure we could find and equal trade that could benefit the both of us. I know Mike P has written many many articles about rotary polishing and I know I haven't read through them all but hopefully during this I can share some new tips and tricks some may have never considered. If someone gave me a tip, and a cow and firecrackers were involved, and it resulted in a better finish, I'd try it!

I'm with you, the more I can learn the better. I'm interested in seeing if we come up with similar results using these products with a rotary.

-

Re: Year Long 3401 Production Review & Rotary Finish Compairson

Originally Posted by 04Golf

I'm a bit confused, is DA haze/ micro marring a normal part of corrections or is something wrong in the process? I was taught that haze was normal due to the aggressiveness of the compound/ pad. Just follow up with a polish to eliminate the haze. Should I be finishing down haze free on my cutting step? I don't get haze all the time depends on the paint but I just polish it out

I tend to think of da haze/micro marring as the dual action equivalent of rotary holograms/buffer trails. Cutting with either one can leave some type scratch pattern behind, but like you said, it can be polished out.

I may be incorrect, but I think a lot of thoughts that dual actions finish so much better than rotaries is because of the scratch pattern let behind. It's easier for our eyes to catch the rhythmic fine lines a rotary can leave versus the random fine lines left by a DA.

-

Super Member

Re: Year Long 3401 Production Review & Rotary Finish Compairson

Originally Posted by hollerstiltner

I tend to think of da haze/micro marring as the dual action equivalent of rotary holograms/buffer trails. Cutting with either one can leave some type scratch pattern behind, but like you said, it can be polished out.

I may be incorrect, but I think a lot of thoughts that dual actions finish so much better than rotaries is because of the scratch pattern let behind. It's easier for our eyes to catch the rhythmic fine lines a rotary can leave versus the random fine lines left by a DA.

Not a fan of haze, even if I get the correction I'm looking for I found haze a pita to get rid of. I rather not have micro marring

-

Re: Year Long 3401 Production Review & Rotary Finish Compairson

Originally Posted by 04Golf

Should I be finishing down haze free on my cutting step?

Great question and the answer is sometimes.

Whether you can finish down haze free during the cutting step depends on,

The paint - Some paints polish better than others and dark colors show haze to your eyes better than light colors. Doesn't mean light colors don't haze it's just harder to see.

The product - As I noted in my previous post it's all about the abrasive technology.

The pad - This actually goes back to the paint as some paints are more sensitive to micro=marring than others.

The tool - Again, this goes back to the paint.

-

Super Member

Re: Year Long 3401 Production Review & Rotary Finish Compairson

12/12/15

Winter Time

This is my second winter test. First test with Menzerna products.

Subject Panel: Right Side/Lexus 8U0

Clear Coat: ChromaPremier Pro 74500S Productive Clearcoat

Activator: ChromaPremier Pro 14305S Normal Activator

Reducer: ChromaPremier Pro 14375S Fast Reducer

Compound: Menzerna Heavy Cut Compound 1000 S34A

Polish: Menzerna Power Finish 2500 PO 203

Polish: Menzerna Super Finish SF-3500 PO 106 FA

Dry Time: 9 hours after bake

Panel was first sanded with 3M 1500 wet/dry paper followed by 3M (02087) Trizact Hookit 3" P3000 Grit Foam Disc on a DA sander with a 3M (05777) Hookit 6" x 1/2" x 3/4" Soft Interface Pad. Note: Skipped 5000 for compound testing

Rotary with 3M Perfect-It Wool Compounding Pad 9" 05719 Menzerna S34A after 4 passes with the buffer set at 1800rpm. The S34a seems to have a very fast initial correction as far as gloss (why I stopped after 4 passes) but I could still see haze and sanding marks upon further inspection with a light, more than I would have with 3M Perfect-It 36060 at 5 passes but S34A had more gloss. Added 2 more passes with additional product to achieve normal correction results. Also, the S34A seemed to clog or build up faster on the pad than the 36060 with equal amounts of product. Results:

Rotary with 3M Perfect-It Plus Foam Polishing Pad 8' 05738/White and then Black Hybrid Polishing Pads and Menzerna PO23 after 7 passes with the buffer set at 1800rpm/DA at speed 5 and 4 both pads. I have to start by saying I think this polish is fantastic. Stayed very wet for all 7 passes and finished out very well. Didn't have to use as much product as 3M Perfect-It 3000 06064. Seemed to finish out slightly better (gloss) than the 3M but did not cut as well as the 3M, but I'm not sure most people could/would notice, just my opinion. Results:

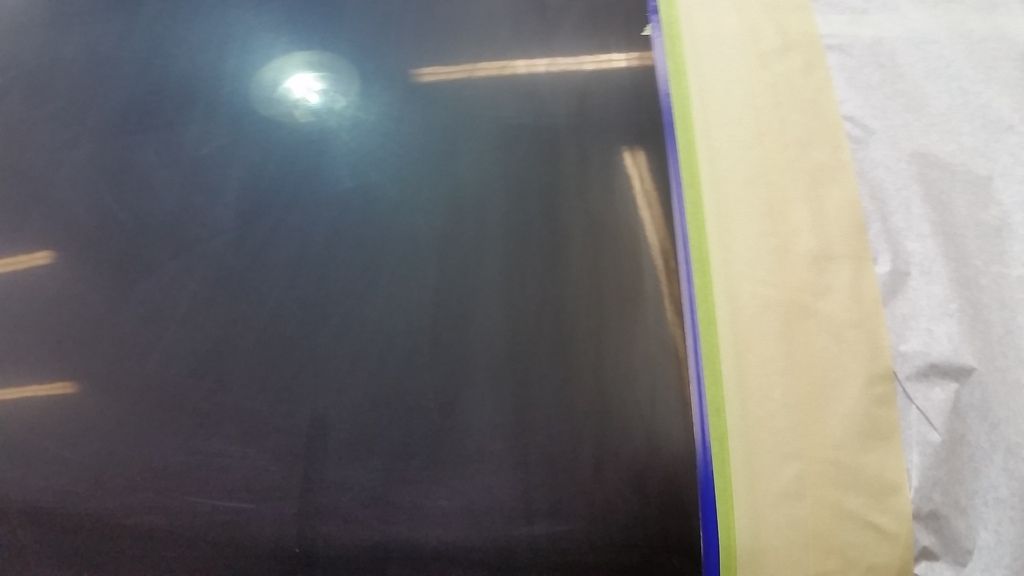

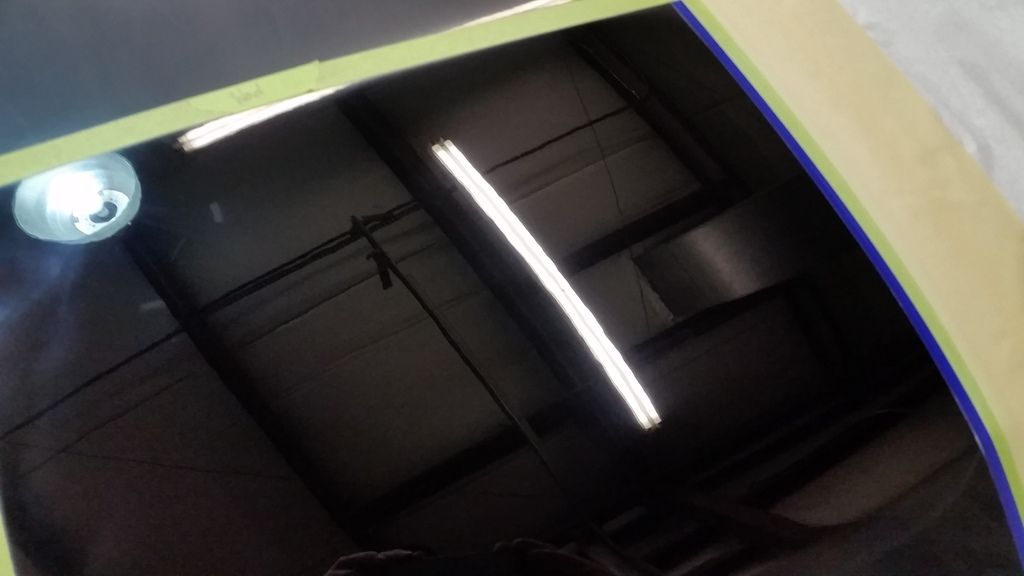

Final step with 3M Perfect-It Plus Ultrafina Foam Polishing Pad 8" 05733/Black and Red Hybrid Polishing Pads and Menzerna Super Finish 106FA with 5 passes at 1800 rpm/DA at speed 5 and 4 and 3 both pads/4, 3 and 2 on the final red pad. More pressure must be applied on a vertical panel vs a horizontal panel, then leaving the buffer barley resting on the surface, slightly lighter than a full weight only rest, by pulling back on the buffer very slightly. This polish finished out to my liking, very impressed. Stayed wet and resulted in a very high gloss. I would like to see how the 3800 looks after this step. That will be done in the next test. Results:

When I polished the vehicle, I used rotary polishing steps on the quarter panel and DA polishing steps on the rear door (both panels rotary only first step). Once again with the weather being cloudy, I can not honestly say which finishing process is better even with my inspection light. At this point there is nothing else I can do but hope for a sunny weekend for any real conclusive results. Don't worry, there will be many opportunities with perfect weather to check for holograms this year! Here are some out door shots 1/4(rotary) vs door (DA):

Rotary:

DA:

Similar Threads

-

By Mike Phillips in forum Flex Polishers

Replies: 4

Last Post: 01-26-2024, 10:12 PM

-

By Mike Phillips in forum Flex Polishers

Replies: 4

Last Post: 12-14-2020, 09:38 AM

-

By Mike Phillips in forum Product Reviews by Mike Phillips

Replies: 13

Last Post: 08-03-2020, 11:36 AM

-

By wantboost in forum Auto Detailing 101

Replies: 12

Last Post: 05-12-2017, 11:36 AM

-

By ron.logan in forum Auto Detailing Tools and Accessories

Replies: 22

Last Post: 10-19-2009, 11:01 PM

Members who have read this thread: 1

Members who have read this thread: 1

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

|

| S |

M |

T |

W |

T |

F |

S |

| 31 |

1

|

2

|

3

|

4

|

5

|

6

|

|

7

|

8

|

9

|

10

|

11

|

12

|

13

|

|

14

|

15

|

16

|

17

|

18

|

19

|

20

|

|

21

|

22

|

23

|

24

|

25

|

26

|

27

|

|

28

|

29

|

30

| 1 | 2 | 3 | 4 |

|

Thanks:

Thanks:  Likes:

Likes:  Dislikes:

Dislikes:

Reply With Quote

Reply With Quote

Bookmarks