Thanks: 0

Likes: 0

Dislikes: 0

-

Diamond Plate Aluminum from Dullsville to Mirror Shine on a 1947 Chevy Pickup

Diamond Plate Aluminum from Dullsville to Mirror Shine on a 1947 Chevy Pickup

Dullsville

Mirror Shine

Last week Todd Helme and I Tag-Teamed the diamond plate bed in my friend Lew's 1947 First Series Chevy.

A HUGE thank you to Todd for taking the pictures from this project and creating this thread writing in 3rd person.

I think it's pretty easy to see that not only is Todd a top notch detailer and true artist of the craft but also a darn good writer and photographer.

Let the story begin...

While there are many metal polishes that do a great job at shining metals such as aluminum and creating a high-gloss finish, many lack the power to do heavy correction. This is because, much like polishing paint, doing heavy correction on metal requires aggressive compounding and polishing to remove deeper scratches and create a visibly level surface that will reflect light evenly. Many aggressive metal compounds will scour and haze the surface and may leave it duller, requiring subsequent steps to restore the gloss.

High level metal polishing is usually reserved for metal polishing professionals who use a variety of polishing bars and a buffing wheel. The BLACKFIRE Metal Polishing System was designed to give enthusiasts, who have experience using a machine polisher, the ability to achieve professional levels of correction and gloss. Metal polishing is a dirty job, but the reward is worth it.

What you will need:

A rotary polisher or dual-action polisher: Because of the aggressive abrasives used in metal polishing you will generally achieve better results using a rotary polisher.

The BLACKFIRE Metal Polishing System: This system consists of a 3 products designed to cut, polish, and final polish aluminum and stainless steel. BLACKFIRE Heavy Cut Aluminum Compound is an aggressive 'pre-polish' that removes heavy staining, water etching, and scratches; BLACKFIRE Fine Cut Aluminum Polish is an aggressive polish that remove compounding marks, stains, and restores gloss to aluminum and stainless steel; BLACKFIRE Wet Diamond Aluminum Show Polish is an ultra fine liquid rogue that restores gloss and creates a super reflective surface.

Pads: The BLACKFIRE Metal Polishing System is designed to be used with specifically blended wool pads for the first two steps and a polishing foam for the final step. You can use different wool or foam pads for the compound to achieve different effect, but the BLACKFIRE Metal Wool Pads make it easy to make sure you have the right pad for the job.

A lot of general purpose microfiber towels: Metals such as aluminum and stainless steel will “bleed” black residues when polished. This black residue will permanently stain towels and render them unfit for paint work. It is recommended to have an ample supply of general duty microfiber towels on hand.

Appropriate clothing and safety equipment: Polishing metal is dirty work (because of the aforementioned bleeding of the metal). Use should were eye protection (eye glasses at a minimum or safety goggles), work clothing, and high quality gloves.

A Pad Spur: Use a pad spur or brush to clean the and fluff the wool pads frequently. Clean pads will not only polish faster and more effectively but reduce the amount of scouring left behind on the surface.

A Pad Cleaner: A Pad Cleaner makes cleaning the pads on the fly easy. For this we used the Grit-Guard Pad Cleaning System.

Good helpers: Polishing metal, much like polishing paint can be very time consuming.

Getting started:

The first step in getting started is to evaluate the metal surface and clean it.

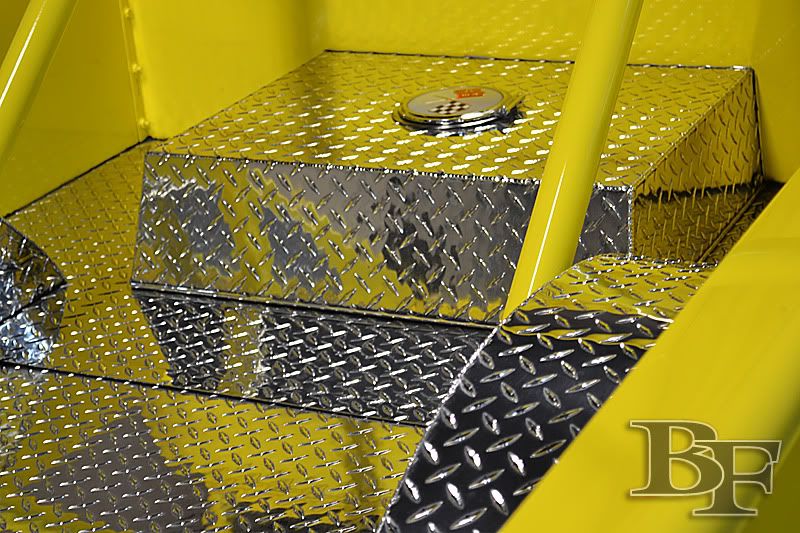

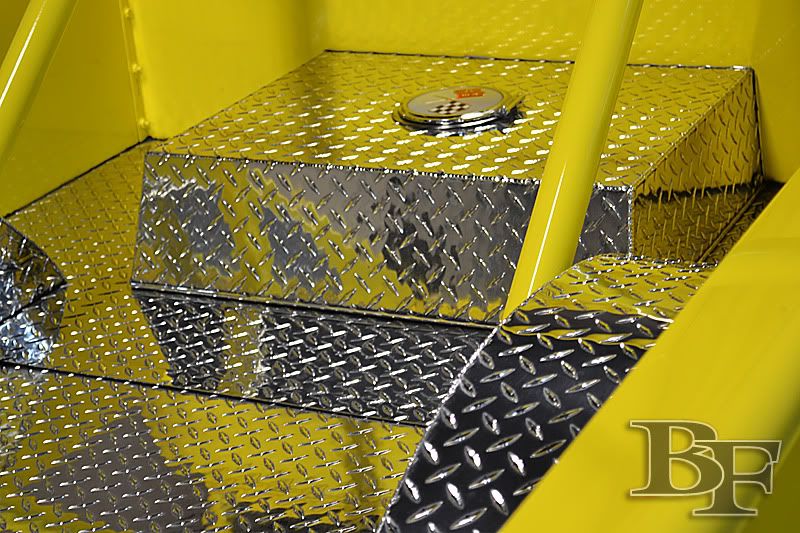

The back of this custom 1947 hot rod pick up truck was covered in custom diamond-plate aluminum.

Note: Diamond plate can be made from aluminum, steel, o stainless steel. Generally stainless steel is going to be harder to polish (it is a tougher material) than most aluminum, similar to scratch resistant clear coat. The process is the same, but stainless and harder metals may require more compounding.

The diamond plate had stains, etching, and was generally dull in appearance.

Todd used BLACKFIRE Wet Diamond Waterless Wash on all of the surrounding paint as well as the diamond plate itself.

Test Spot

Much like polishing paint, it is best to start with a small test spot to dial in your process completely, before repeating that process over the entire surface. Different metals may require different techniques, and while not used for the purpose of the following, it is a good idea to start with the least aggressive method first, and work up until you find the process that works best.

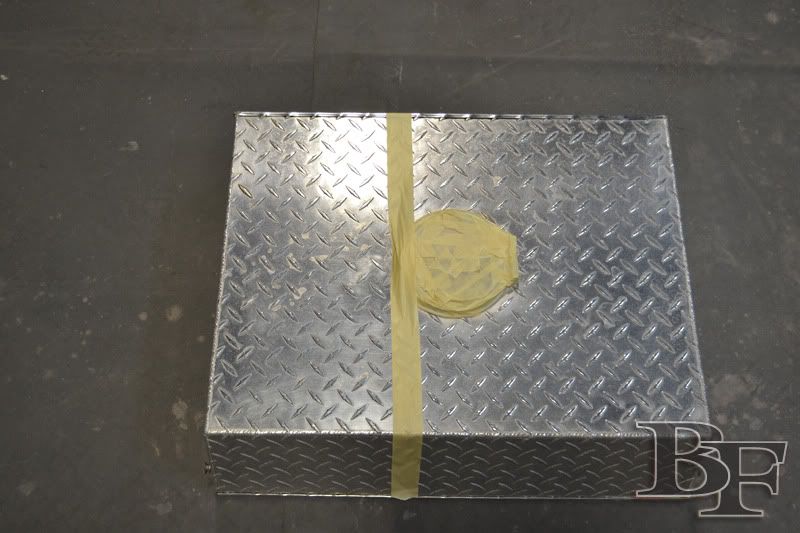

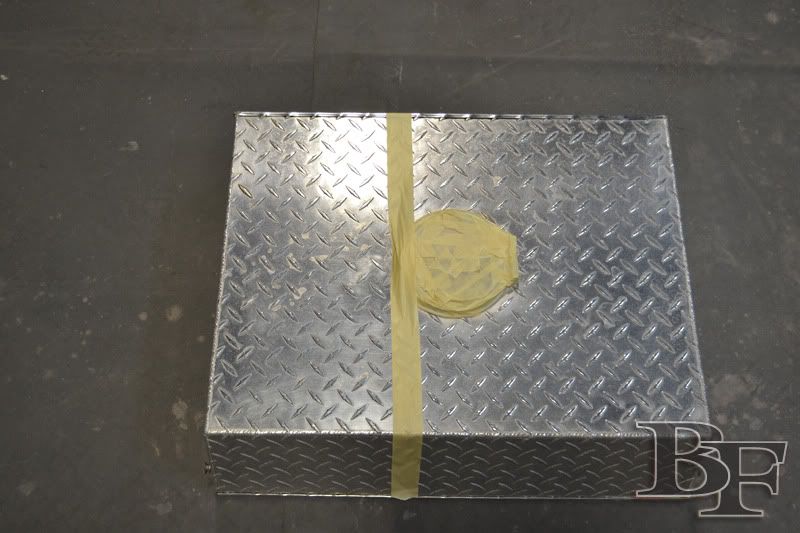

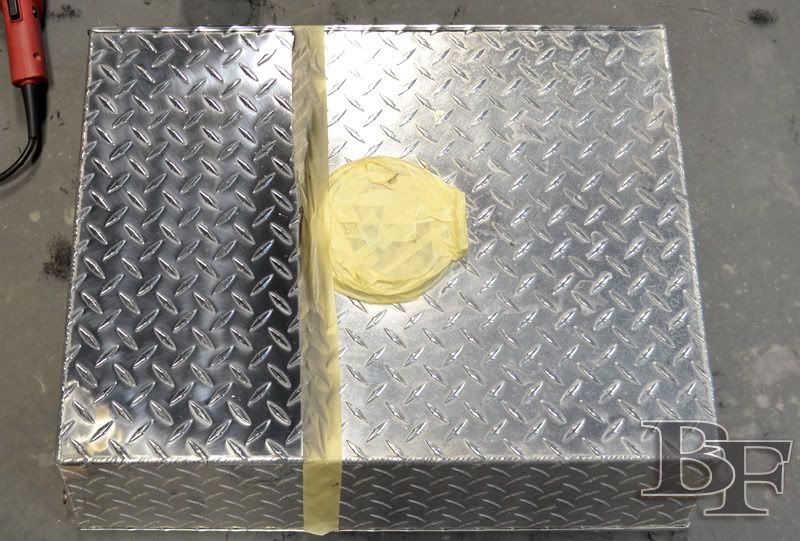

The gas tank cover, removed prior to the previous pictures, served as the the test panel.

Meguiar's Masking Tape was applied to the vintage (1966 Corvette) gas lid as well as to mask off a section for working.

Step One Compounding:

BLACKFIRE Heavy Cut Aluminum Compound is designed to restore weathered, chalky, dull, and spotted bare metals. It can be used with great results on aluminum, brass, copper, magnesium, and blended metals. As step 1 in the BLACKFIRE Metal Polishing System, BLACKFIRE Heavy Cut Aluminum Compound removes surface rust from chrome and stains from stainless steel. It's the first step in restoring a mirror-shine to bare metals. This is the workhorse of the BLACKFIRE Metal Polishing System. This is the polish that does the heavy correction. If we were working on paint, this product would be called a compound. Technically, BLACKFIRE Heavy Cut Aluminum Compound is a pre-polish. It's to be used before a gloss-restoring polish. It creates a uniform, SATIN finish ready for "Step Two", gloss polishing. It quickly removes surface rust from chrome and will buff out harsh stains in stainless steel. This is an ammonia-based paste, packed with diminishing-abrasives, formulated to stick to vertical surfaces to make large panel polishing quick and easy.

To achieve best results work BLACKFIRE Heavy Cut Aluminum Compound for an adequate time to ensure the complete break down of the abrasives.

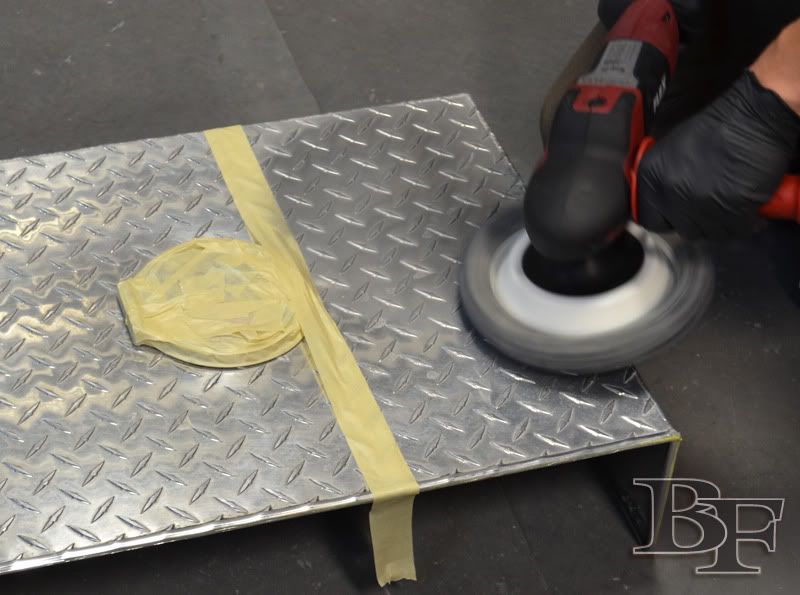

You can use BLACKFIRE Heavy Cut Aluminum Compound with a rotary or Dual-Action polisher, although quickest results will be achieved with the direct drive rotary polisher. You can apply it with the recommended BLACKFIRE Stage 1 or Stage 2 Wool pads, or with a variety of moderate to heavy cutting foam pads if needed.

The tools used: Here is BLACKFIRE Heavy Cut Aluminum Polish, next to the BLACKFIRE Stage 2 Wool Pad, on a FLEX PE14-2-150 Rotary Polisher.

Apply BLACKFIRE Heavy Cut Aluminum Compound directly to the panel using a soft brush, such as this 1 inch detailing brush and spread into a light, even coat.

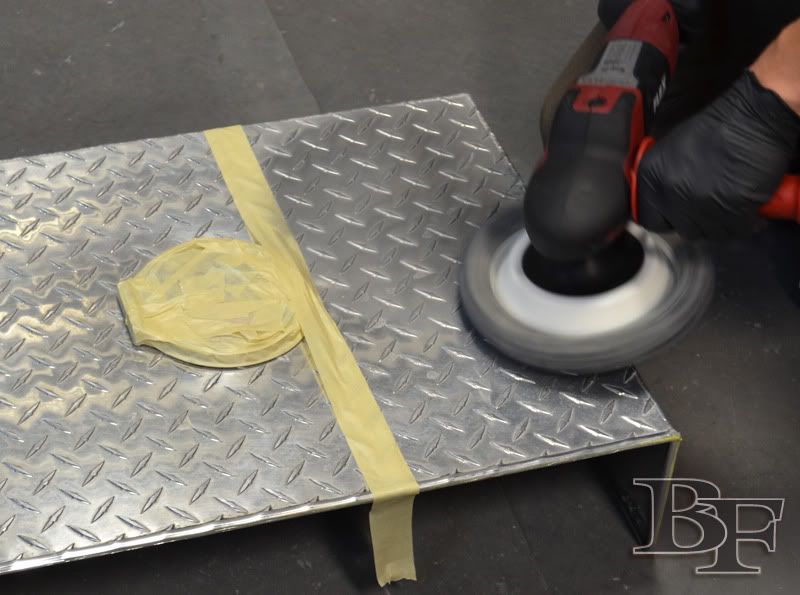

Todd spreads the polish at low rpm (>1000) then increase speed and pressure, working at 1500 rpm until the the polish begins to clear in slow, over lapping passes.

You can clearly see the black that has “bleed” from the metal on the face of the pad. This from the trace amounts of aluminum that have been polished away instantly oxidizing.

A quick inspection reveals that a little more compounding would yield a better result. Remember to take your time on the first step, it lays the foundation for the shine that is about to come.

Todd added at a little more compound on top of the piece and worked it in slowly using the technique described above.

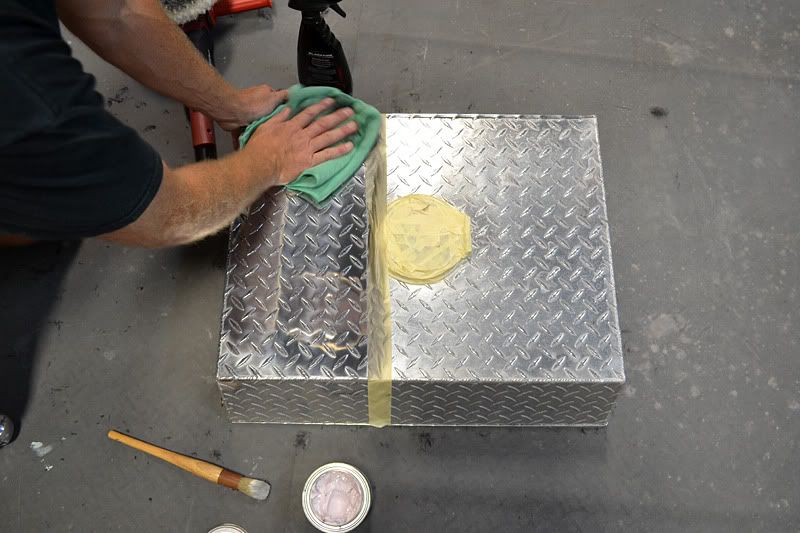

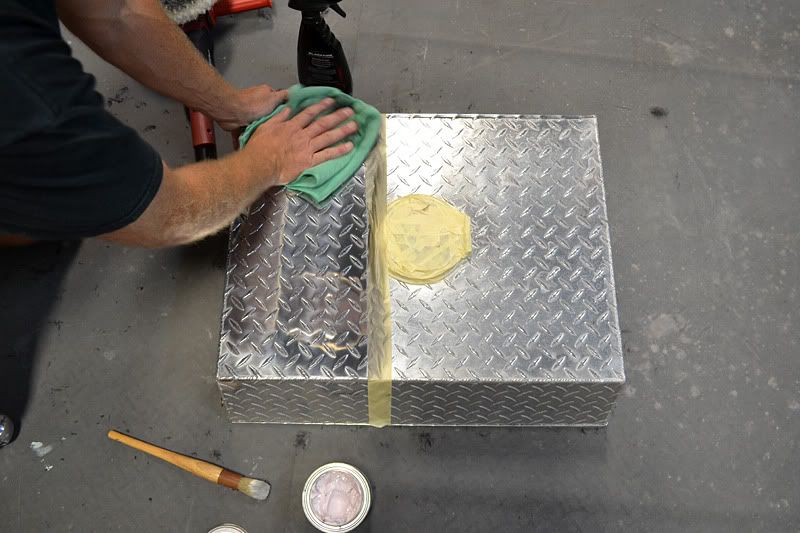

When you are happy with the results use a general purpose microfiber towel to remove the residue and prevent scratching.

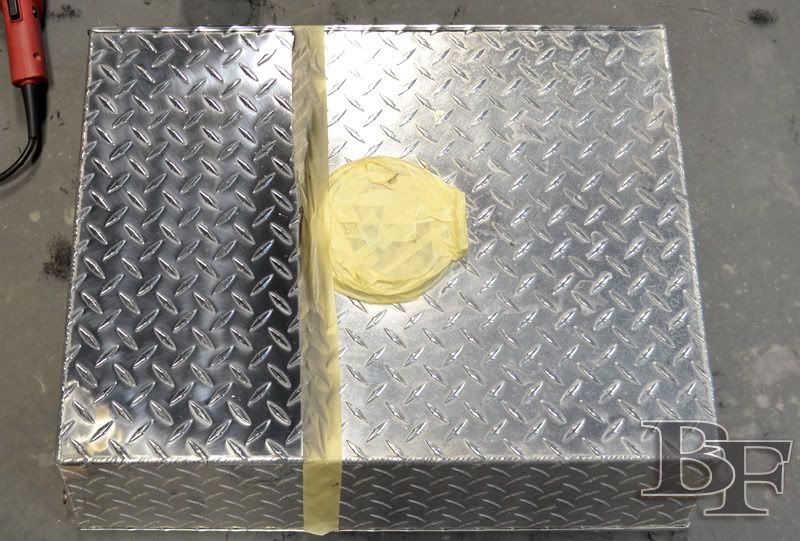

The results after step one show a much better finish that is far more reflective then the previous side and is devoid of deeper scratches and staining. The second step will refine the surface and produce a higher gloss finish.

Step Two Polishing/Refinement

BLACKFIRE Fine Cut Aluminum Polish is step two of the BLACKFIRE Metal Polishing System. It removes minor oxidation, haze, light blemishes and it restores a brilliant shine on bare metals such as aluminum, brass, copper, magnesium and blended metals. BLACKFIRE Fine Cut Aluminum Polish quickly shines chrome and restores a like-new finish on stainless steel. It's the ultimate polish for bare metals! It is excellent as a one-step metal cleaner on near-perfect finishes.

This is an ammonia-based paste, combined with jewelers rouge and very fine diminishing-abrasives. BLACKFIRE Fine Cut Aluminum Polish is formulated to stick to vertical surfaces to make polishing large panels quick and easy.

In some cases, you may need to use a pre-polish to get the maximum shine. If the metal is slightly tarnished, just starting to oxidize or has very fine blemishes, BLACKFIRE Fine Cut Aluminum Polish will easily remove the oxidation and tarnish to create a bright, chrome-like shine. If the metal is quite dull and chalky from years of weathering or severely pitted or water-stained, you should pre-polish first with BLACKFIRE Heavy Cut Aluminum Polish.

To achieve best results work BLACKFIRE Fine Cut Aluminum Polish for an adequate time to ensure the complete break down of the abrasives.

You can use BLACKFIRE Fine Cut Aluminum Polish with a rotary or Dual-Action polisher, although quickest results will be achieved with the direct drive rotary polisher. You can apply it with the recommended BLACKFIRE Stage 2 or Stage 3 Wool pads, or with a variety of moderate cutting to polishing foam pads if needed.

The tools used: Here is BLACKFIRE Fine Cut Aluminum Polish, next to the BLACKFIRE Stage 1 Wool Pad, on a FLEX PE14-2-150 Rotary Polisher.

QUICK TECH TIP:

Using a new wool pad will cause it to shed wool fibers like crazy. Combined with the black residue from metal polishing and you are guaranteeing yourself a mess. Mike Phillips conditions the fresh BLACKFIRE Stage 1 Metal Polishing Pad with a Grit Guard Pad Washer prior to use.

Similar to using Heavy Cut Aluminum Compound, apply BLACKFIRE Fine Cut Aluminum Polish with a soft brush to the surface.

Work in slow controlled passes at about 1200 RPM using firm pressure until the metal really begins to bleed. As Mike worked the polish back and forth the brilliant shine of the aluminum was visible under the black residue.

With the polishing complete, remove the residue and inspect. For metal polishes to be effective they have to stick were they are applied with minimal sling. This can make their removal a little more difficult. Mike uses BLACKFIRE Wet Diamond Waterless Wash to make buffing off the residues much easier.

The finish now has considerably more gloss than before and things are moving forward. The surface is now ready for the final polishing for maximum gloss.

-

Re: How to use the BLACKFIRE Metal Polishing System to polish Diamond Plate Aluminum

Continued...

Step Three Final Polishing

BLACKFIRE Wet Diamond Aluminum Show Polish is the state-of-the-art metal polish for taking aluminum to a true, mirror-like finish. This is over-the-to shine for competition, concours events or just plain showing off! This is like a jeweling polish for your paint, designed to amp up the gloss and create the sharpest, most brilliant reflections possible.

BLACKFIRE Wet Diamond Aluminum Show Polish is a finishing polish for aluminum that has already been polished with BLACKFIRE Fine Cut Aluminum Polish. It takes the existing bright, chrome-like shine and further burnishes the finish to a mirror-like shine. Use it to keep already polished metals looking their best as well. This ultra fine polish does not have the ability to correct visible defects. If your polish is less-than-perfect use BLACKFIRE Fine Cut Aluminum Polish first.

BLACKFIRE Wet Diamond Show Polish is a pine-based formula packed with nano, ceramic-dust particles. It's these super-hard yet micro, micro fine particles that are the secret to this polish’s phenomenal shine. Wet Diamond Show Polish is specifically designed for sheet aluminum, diamond plate, billet aluminum and cold rolled Alcad aviation grade aluminum.

You can use BLACKFIRE Fine Cut Aluminum Polish with a rotary or Dual-Action polisher, each will provide great results. You can apply it with the recommended BLACKFIRE Stage 1 Wool pad, or with a polishing foam.

Note: Wet Diamond Aluminum Show Polish works great with foam polishing pads, but most foam pads can tear when applied to the sharp edges of metal. Using a Kompressor pad helps alleviate these problems.

The tools used:

Here is BLACKFIRE Wet Diamond Aluminum Show Polish, next to a white 6 inch Kompressor Pad, on a FLEX PE14-2-150 Rotary Polisher. Mike is brushing on the polish in the picture.

Before brushing the Aluminum Show Polish on it is important mix it thoroughly. Mike uses the handle end from the 1 inch detailing brush to mix the polish into a creamy state.

Then brushed it on to the panel.

Work in slow, overlapping passes keeping your speed at around 1000 RPM until the residue is mostly clear (it will have a black tint).

Again Mike uses BLACKFIRE Wet Diamond Waterless Wash to aid in the removal of polish residue and reveal a glistening surface underneath.

With the process dialed in Mike added some DP Polishing Pad Rejuvenator to the Grit Guard Pad Cleaner in order to add in cleaning the pads on the fly. At this point the entire bed still had to be done.

Repeat the appropriate steps over the rest of the working surface:

With the process dialed in, repeat the process that worked over the rest of the area, inspecting frequently and cleaning your polishing pads often.

Todd worked with the the truck owner, Lew, to polish the rest of the tank cover.

Mike got started on the bed of the truck.

With the tank cover glistening, Todd jumped in the bed and started working the smaller areas using several rotary extenders and small 3 inch pads. Note that a microfiber towel was laid on the bed to prevent scratching and several Cobra Microfiber towels were taped on the inner fenders to avoid scratching the paint with the polishing cord.

Both Todd and Mike have a lot of experience rotary polishing, a couple of times they got a little close for comfort.

The last step: DA Polishing

After carefully inspecting the finish, very faint holograms could be detected from the soft aluminum finish. Todd and Mike choose to quickly polish the area using DA polishers to remove the hologram effect. They armed Porter Cable 7424 XP Polishers with Tangerine Hydro-Tech pads and made two to three passes over each area with moderate pressure.

The final clean up

Mike and Todd removed the masking tape from around the bed and wiped the diamond-plate cleaning using BLACKFIRE Wet Diamond Waterless Wash. Any splatter was also removed from the paint. Lew bolted the tank cover on all that was left was to enjoy the high-gloss finish created by the BLACKFIRE Metal Polishing System.

Finally Lew headed home with after a brief rain storm. The picture of the flamed hot rod in front of the flamed Meguiar's Detailing Rig made for a cool parting shot.

-

Super Member

Re: How to use the BLACKFIRE Metal Polishing System to polish Diamond Plate Aluminum Re: How to use the BLACKFIRE Metal Polishing System to polish Diamond Plate Aluminum

Mike,

How tough was the diamond plate on the pads, especially the Kompressor? Did they get pretty beat up?

Any plans for a sealant to help the shine last?

I bet Lew was pretty happy!

Randy

-

Super Member

Re: How to use the BLACKFIRE Metal Polishing System to polish Diamond Plate Aluminum

Wow - That is night and day. It sure looks labor intensive but well worth it for the end result. Great work Todd & Mike!

-

Re: How to use the BLACKFIRE Metal Polishing System to polish Diamond Plate Aluminum

-

Re: How to use the BLACKFIRE Metal Polishing System to polish Diamond Plate Aluminum

Originally Posted by ZimRandy

Mike,

How tough was the diamond plate on the pads, especially the Kompressor? Did they get pretty beat up?

Wool pads work really well for this especially for the initial cut. The fibers that make up a wool cutting pad are coarse and strong so they'll take a lot of abuse. It's for these same reason you don't want to finish a car using a a wool pad as the fibers are coarse and strong and you'll leave swirls behind.

We chose the Kompressor pads because they are slotted and the individual slots will give way versus tear like a solid foam pad. They did show signs of wear after the job was done but keep in mind we were really punishing all pads during this project.

Originally Posted by ZimRandy

Any plans for a sealant to help the shine last?

Yes but first I think Lew was going to carefully wash the truck and the truck bed.

Originally Posted by ZimRandy

I bet Lew was pretty happy!

Randy

Ecstatic is the word I would use...

-

-

Regular Member

Re: How to use the BLACKFIRE Metal Polishing System to polish Diamond Plate Aluminum

The blackfire polish looks alot like the wolfgangs, whats the difference? Jonathan

-

Re: How to use the BLACKFIRE Metal Polishing System to polish Diamond Plate Aluminum

Originally Posted by ohmy34

The blackfire polish looks alot like the wolfgangs, whats the difference? Jonathan

Personal preference... Todd wanted to do an article on metal polishing and just by coincidence I had some metal to polish to take care of with Lewis's truck.

Most quality metal polishes work when it comes to the grunt work portion, the major differences between metal polishes, at least to me is the finishing polishes and to date I like the Meguiar's NXT All Metal Polysh, at least for my leg.

Cosmin and me...

-

Re: How to use the BLACKFIRE Metal Polishing System to polish Diamond Plate Aluminum Re: How to use the BLACKFIRE Metal Polishing System to polish Diamond Plate Aluminum

This is Lew, with the '47 truck, and YES I am Ecstatic about the finished work.. Mike and Todd really know their Sh..... I mean Stuff !!!

Similar Threads

-

By Greg5OH in forum Tricks, Tips and Techniques

Replies: 35

Last Post: 05-13-2016, 01:36 PM

-

By kevincolby650 in forum Ask your detailing questions!

Replies: 20

Last Post: 08-22-2013, 10:23 PM

-

By Mike Phillips in forum What's In The Garage?

Replies: 9

Last Post: 01-13-2012, 03:32 AM

Members who have read this thread: 1

Members who have read this thread: 1

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

|

| S |

M |

T |

W |

T |

F |

S |

| 31 |

1

|

2

|

3

|

4

|

5

|

6

|

|

7

|

8

|

9

|

10

|

11

|

12

|

13

|

|

14

|

15

|

16

|

17

|

18

|

19

|

20

|

|

21

|

22

|

23

|

24

|

25

|

26

|

27

|

|

28

|

29

|

30

| 1 | 2 | 3 | 4 |

|

Thanks:

Thanks:  Likes:

Likes:  Dislikes:

Dislikes:

Reply With Quote

Reply With Quote

Bookmarks